Rail head grinding

RAIL HEAD GRINDING WITH ABRASIVE SEGMENTS

The main purpose of the rail head grinding process is to reprofile the desired shape of the head and to remove rail defects which appear due to progressive wear. The operation is performed using lightweight track mounted grinding machines or heavy duty machines

ANDRE abrasive tools proposed for the operation are based on our large experience in railway industry and allow to achieve required surface quality together with high efficiency.

| TYPE 3120

3120 - B/A x C x L/L1

|

Examples of implemented abrasive tools in industry [*] |

||

|

Type |

Dimensions [mm] |

Characteristics |

|

3120 |

66/65x90x155/140 |

99A36T5B520 |

[*] Ask the Sales Department about the full offer and available characteristics.

RAIL HEAD FACE GRINDING

Reprofiling of the desired head shape and removal of defects created during exploitation is carried out with the use of lightweight track mounted grinding machines or heavy duty machines

ANDRE grinding wheels help to achieve the required surface quality with high efficiency.

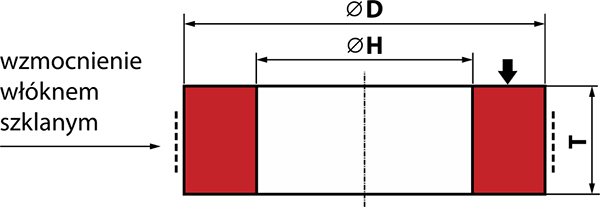

| TYPE 35X | TYPE 36 | TYPE 36X

35X - D x T x H - no. pic.

36 - D x T x H - no. pic.

36X - D x T x H - no. pic.

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

35X |

250x85x150 |

3ZRA16R7B765 |

50 |

|

36 |

150x72x56 |

95A16P6B97 |

50 |

|

36 |

150x80x56 |

95A16P6B97 |

35 |

|

36X |

260x85x153 |

10ZRA12W8B732 |

50 |

[*] Ask the Sales Department about the full offer and available characteristics.

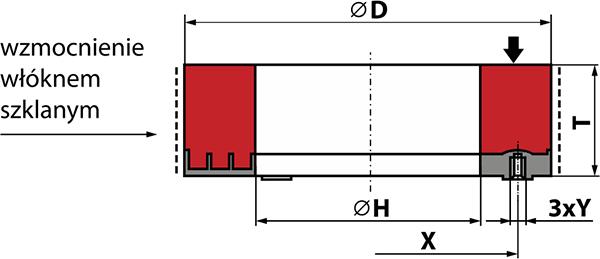

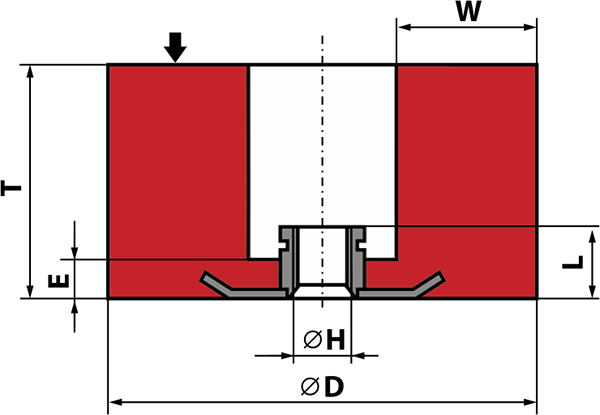

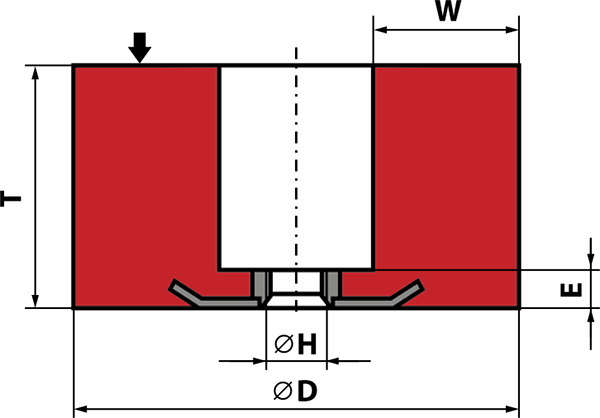

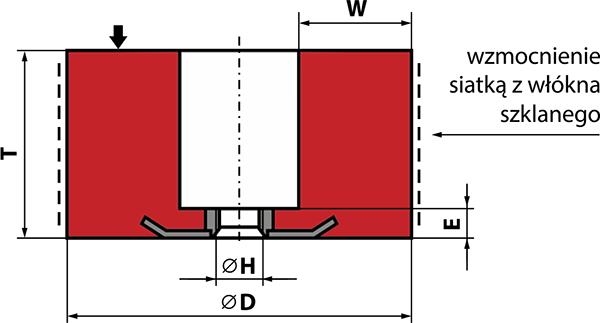

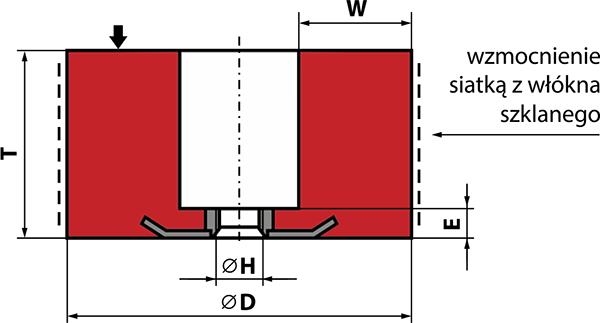

| TYPE 6001 | TYPE 6002 | TYPE 6003 | TYPE 6003X | TYPE 6004 | TYPE 6005

6001 - D x T x H - W...E...

6002 - D x T x H/L - W...E...

6003 - D x T x H - W...E...

6003X - D x T x H - W...E...

6005 - D x T x H/L - W...E...

6004 - D x T x H - W...E...

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

6001 |

80x72x5/8”-W20E20 |

95A16P5B |

40 |

|

6002 |

125x65xM20/23-W37E13 |

95A16QB |

35 |

|

6002 |

150x65xM20/23-W25E18 |

95A16QB97 |

40 |

|

6002 |

100x110xM20/28-W25E23 |

ZRA16R5B97 |

40 |

|

6003 |

100x110xM20L-W20E25 |

95A20QB |

40 |

|

6003 |

100x110xM20L-W20E25 |

95A14QB |

40 |

|

6003 |

150x55xM20-W42,5E18 |

95A16NB |

40 |

|

6003X |

100x110xM20L-W25E24 |

95A16Q5B559 |

40 |

|

6004 |

152x80xM20-W50E18 |

10ZRA16T7B |

63 |

|

6005 |

120x110xM20L-W25E20 |

95A16P5B559 |

40 |

[*] Ask the Sales Department about the full offer and available characteristics.

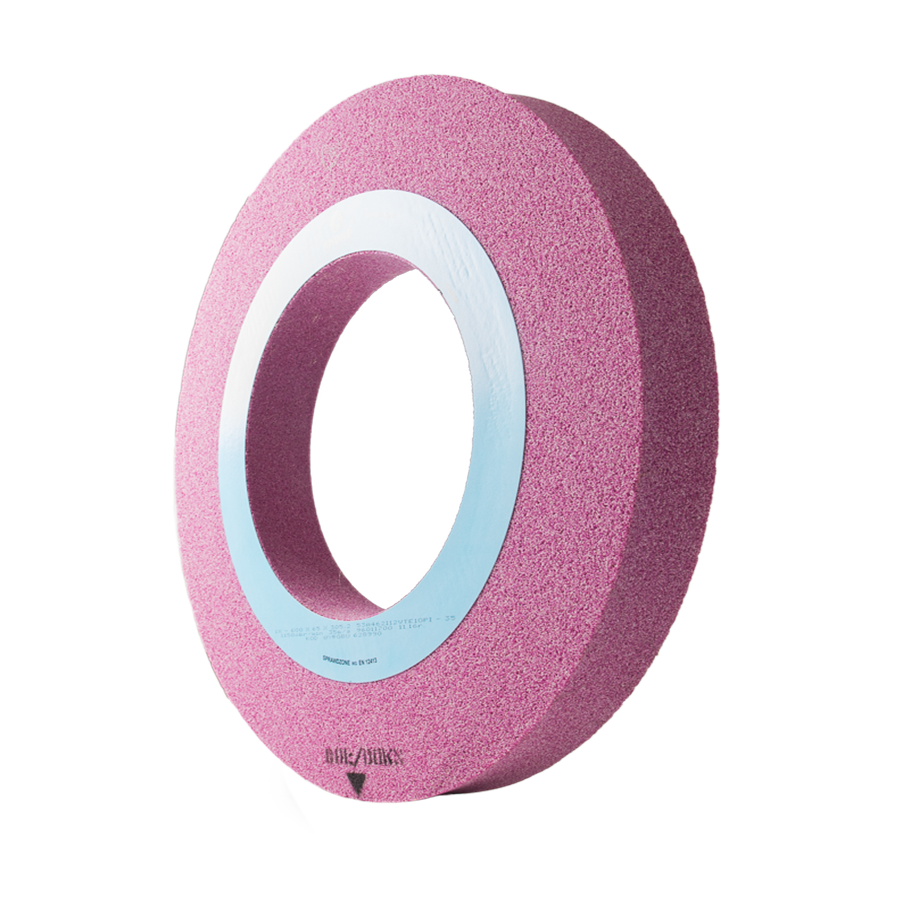

RAIL HEAD GRINDING WITH PROFILE GRINDING WHEEL

In this grinding process a grinding wheel type 1 with a special profile on its periphery is used on heavy duty railway grinding machine.

ANDRE profile grinding wheels dedicated to this operation have been designed to minimize the impact of temperature on grinding process. Technical characteristics of the wheels we offer ensure required surface quality and long life of the grinding wheel.

| TYPE 1X

6004 - D x T x H - W...E...

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

1X |

600x65x305,2 |

53AY462I12VTE10PP |

35 |

|

1X |

600x65x305,2 |

53AY462I12VTE10PP |

35 |

|

1X |

600x50x305,2 |

53AY462I12VTE10PP |

35 |

|

1X |

800x65x305,2 |

53AY462I12VTE10PP |

35 |

[*] Ask the Sales Department about the full offer and available characteristics.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.