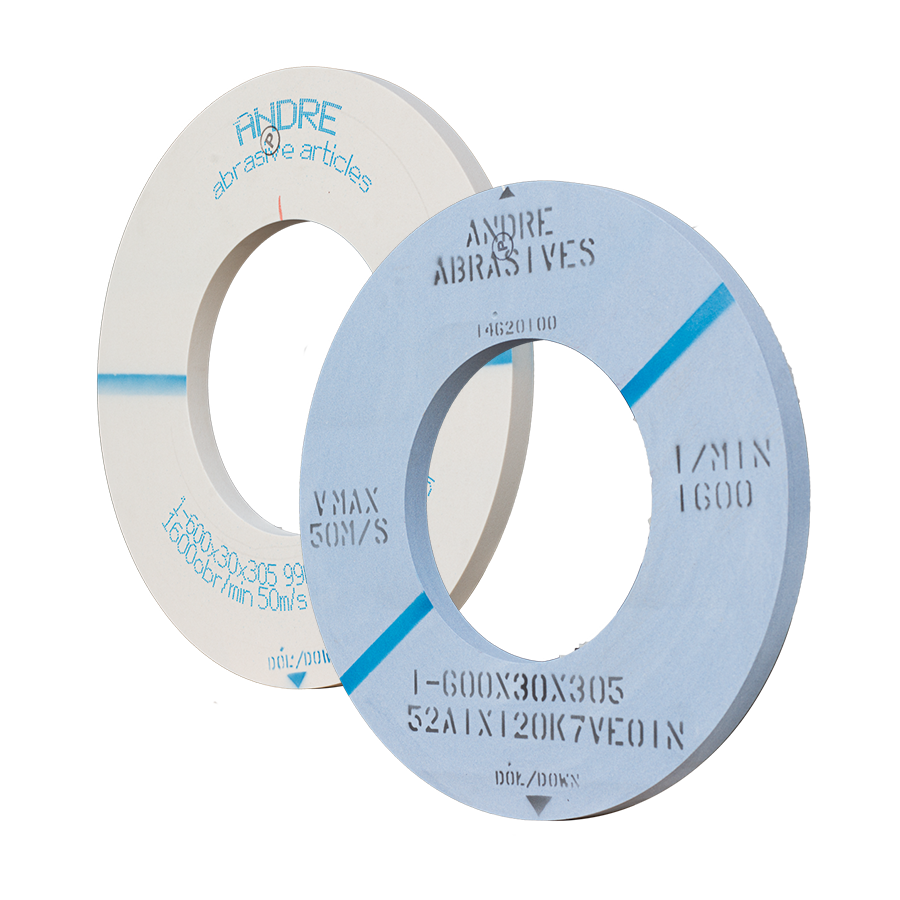

TYPE 1

FLAT GRINDING WHEELS

Flat grinding wheels TYPE 1 are used for precision grinding of various materials and sharpening of cutting tools. They are commonly used in surface grinding, cylindrical grinding (between centers and centerless). They are ideal for hole grinding, profile and contour grinding, and workshop tasks.

They are used on stationary grinding machines, sharpening machines, and in grinding units.

ANDRE TYPE 1 grinding wheels with vitrified bond are manufactured on the basis of brown aluminium oxide (95A), white aluminium oxide (99A), pink aluminium oxide (CRA), black silicon carbide (98C) and green silicon carbide (99C), among others. For special applications, ANDRE also offers other combinations of abrasive grains with excellent performance characteristics.

1 - D x T x H

Examples of labeling:

:

1 - 400x40x127-99A60K7VE01-35

:

1 - 400x40x127-99A60K7VE01-35

Download

Parameters of the offered grinding wheels of the presented type

| TYPE 1 | ||||||||||||

| Dimensions [mm] | ||||||||||||

| D | H - T | 10 | 12,7 | 20 | 25 | 32 | 51 | 76 | 127 | 203 | 305 | 370 |

| 80 | 3 - 50 | x | x | x | ||||||||

| 90 | 3 - 50 | x | x | |||||||||

| 100 | 3 - 80 | x | x | |||||||||

| 125 | 3 - 60 | x | x | x | ||||||||

| 150 | 3 - 50 | x | x | x | x* | |||||||

| 175 | 3 - 50 | x | x | x | ||||||||

| 180 | 3 - 50 | x | x* | x | x* | |||||||

| 200 | 3 - 60 | x | x | x* | x | x* | ||||||

| 250 | 3 - 100 | x | x | x | x | x | ||||||

| 300 | 6 - 130 | x | x | x* | x | |||||||

| 350 | 10 - 100 | x | x | x | x | x | ||||||

| 400 | 10 - 100 | x | x | x | ||||||||

| 450 | 15 -100 | x | x | x | x | |||||||

| 500 | 15 - 200 | x | x | x | x* | x | ||||||

| 600 | 20 - 200 | x | x | x* | ||||||||

| 750 | 20 - 160 | x | ||||||||||

| 800 | 20 - 100 | x | ||||||||||

*) Holes are also made in inch dimensions such as: 31,75; 50,8; 76,2; 203,2; 304,8

SMALL-SIZED GRINDING WHEELS

| TYPE 1 | ||||||||||||||

| Dimensions [mm] | ||||||||||||||

| D | H - T | 2 | 2,5 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 13 | 16 | 20 | 32 |

| 5 | 5 - 15 | x | x | |||||||||||

| 6 | 5 - 15 | x | x | |||||||||||

| 7 | 5 - 15 | x | x | |||||||||||

| 8 | 5 - 15 | x | x | x | ||||||||||

| 9 | 5 - 15 | x | x | |||||||||||

| 10 | 5 - 15 | x | x | x | ||||||||||

| 12 | 5 - 15 | x | x | |||||||||||

| 14 | 5 - 16 | x | x | x | ||||||||||

| 19,5 | 5 - 20 | x | ||||||||||||

| 20 | 5 - 20 | x | ||||||||||||

| 35 | 6 - 50 | x | x | x | ||||||||||

| 40 | 6 - 85 | x | x | x | ||||||||||

| 45 | 6 - 50 | x | x | |||||||||||

| 50 | 6 - 50 | x | x | x | x | x | ||||||||

| 55 | 6 - 60 | x | x | |||||||||||

| 60 | 6 - 60 | x | x | x | ||||||||||

| 65 | 6 - 80 | x | x | x | ||||||||||

| 70 | 6 - 50 | x | ||||||||||||

| 75 | 6 - 50 | x | x | x | ||||||||||

Examples of manufactured grinding wheels of the presented type

For precision grinding of steel, cast steel materials. Grinding wheels used in the following operations: face grinding of shafts in the tusk and centerless, grinding of holes and workshop work.

|

95A |

||||

|

Code |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

In a box |

|

610511 |

350 × 40 × 51 |

95A46K5VTE10 |

35 |

3 |

For precision grinding of steel, cast steel materials. Grinding wheels used in the following operations: face grinding of shafts in the tusk and centerless, grinding of holes and workshop work.

|

CrA |

||||

|

Code |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

In a box |

|

510326 |

125 × 13 × 20 |

CRA60K7VE01 |

35 |

5 |

For precision grinding of non-ferrous metals, hard cast iron, carbide and plastics.

|

98C |

||||

|

Code |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

In a box |

|

620202 |

400 × 50 × 127 |

98C60K7VC01 |

35 |

2 |

The presented abrasive tools ANDRE ABRASIVE ARTICLES have been manufactured based on knowledge and long-term experience of cooperation with customers.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.