ABRASIVE TOOL MOUNTING SYSTEMS

Examples of popular solutions for mounting abrasive tools in grinding equipment

Grinding machines are designed for various grinding wheel and segment mounting systems. Due to safety regulations, elements that directly match the grinding wheel must meet standard requirements.

Popular solutions for mounting abrasive tools

Among the group of the most popular solutions, one can find:

• center bore and clamping flange

• threaded inserts in the grinding wheel or segment

• mounting by means of a backplate

• segments mounted in the holder

• mounting with a pin.

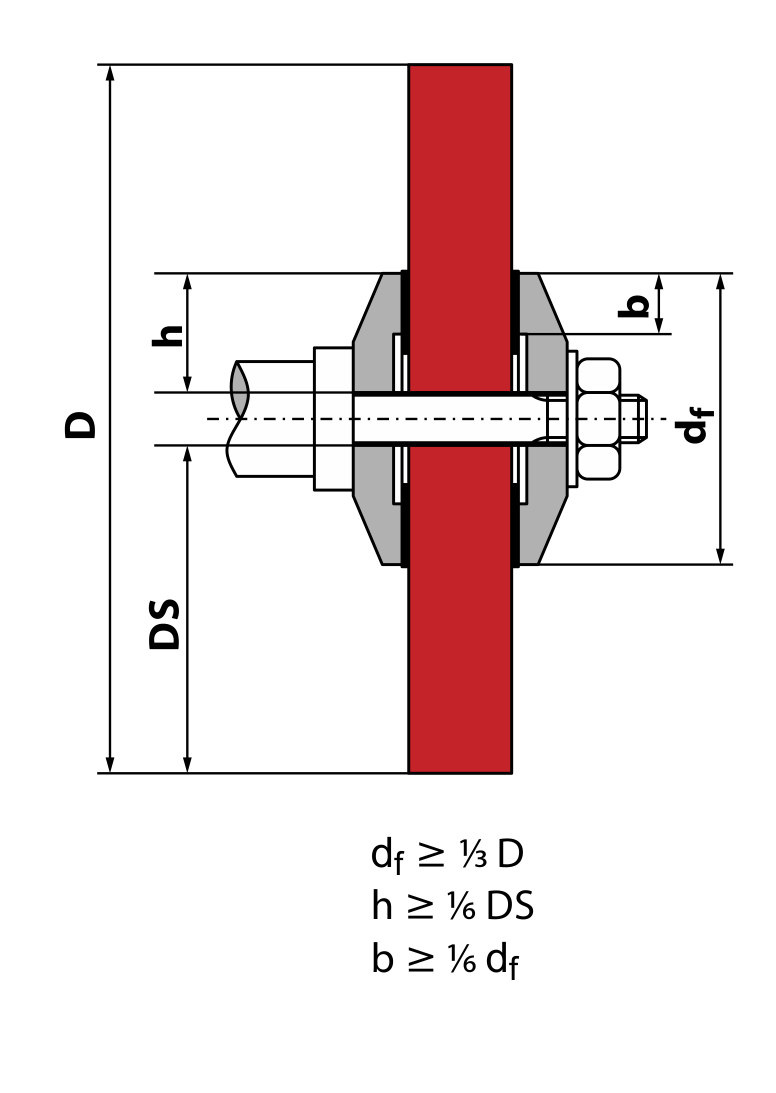

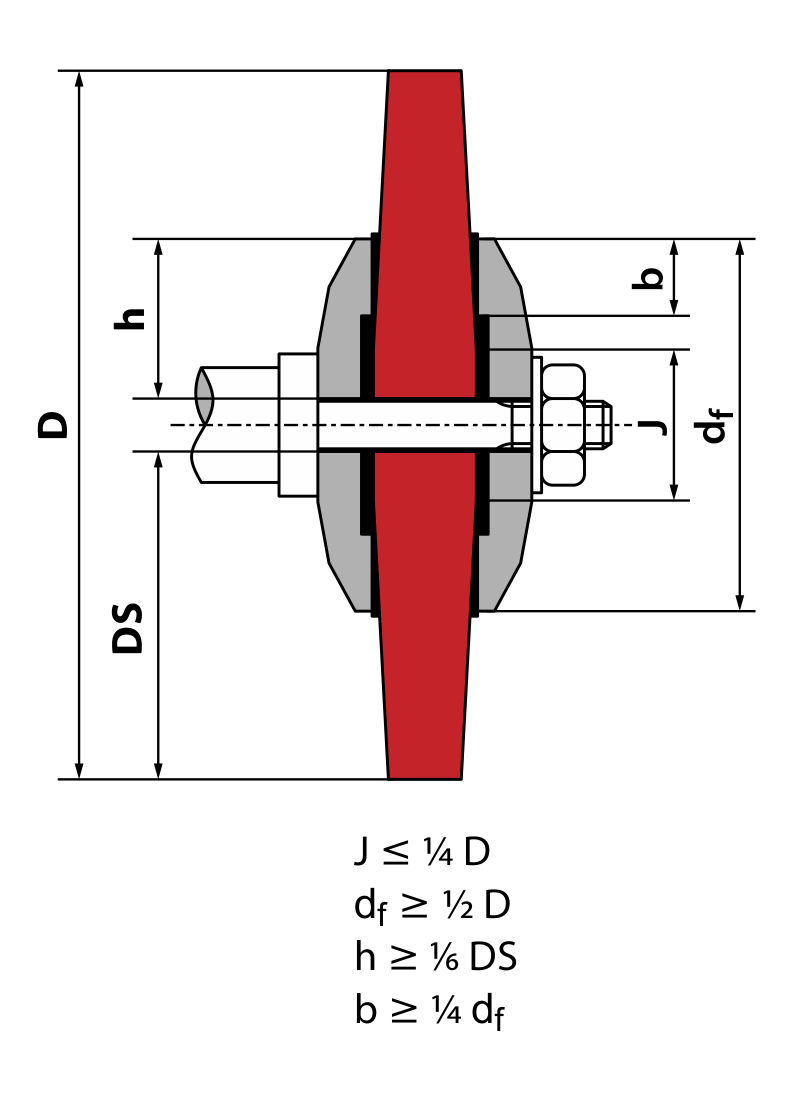

Designations used in assembly system overview drawings

Q = H / D

Q - diameter ratio

D - outside diameter of the grinding wheel

H - diameter of the wheel bore

df - flange diameter of the wheel adaptor

Ds = 1/2 (D - H) - height of the grinding wheel side surface

h - coverage

b - width of the mounting surface

Mounting system with clamping flanges for grinding wheels with small central bore Q ≤ 0.20

Mounting system using hubbed flanges for flat grinding wheels with large central hole Q > 0.20

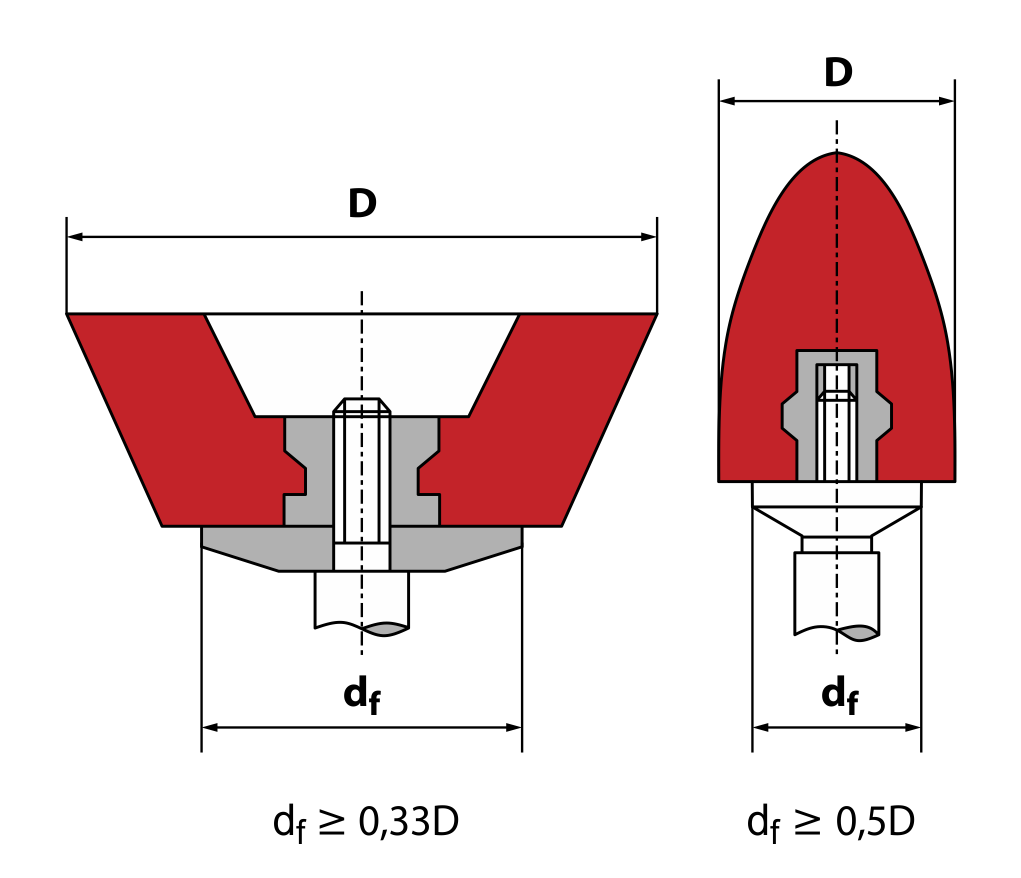

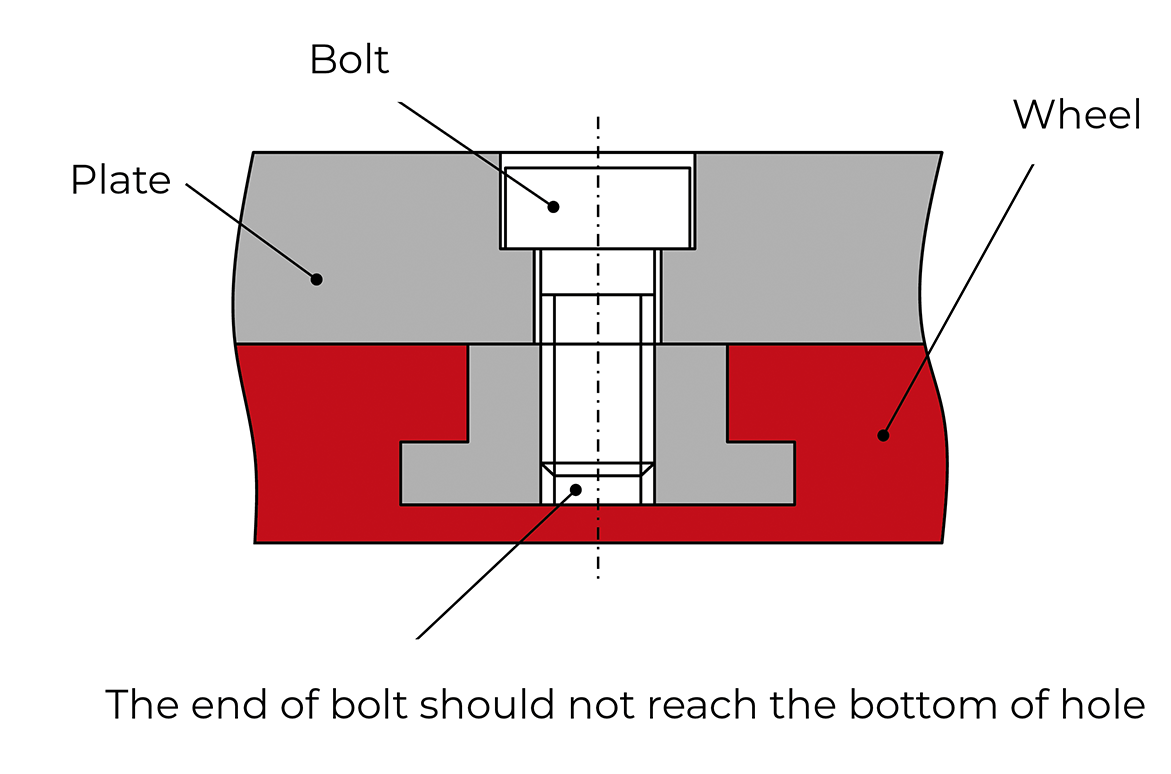

Mounting system for cup wheels, plug or cone with a central threaded insert

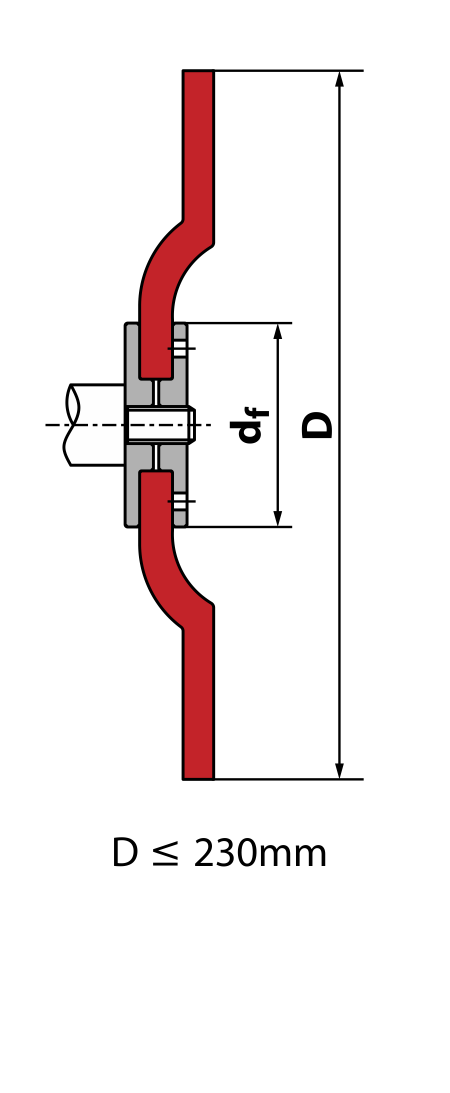

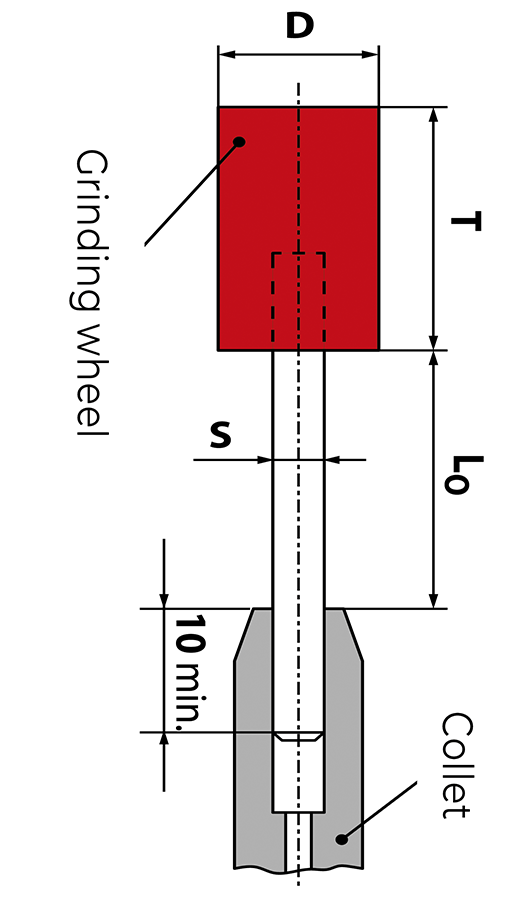

Mounting system in case of mounted points

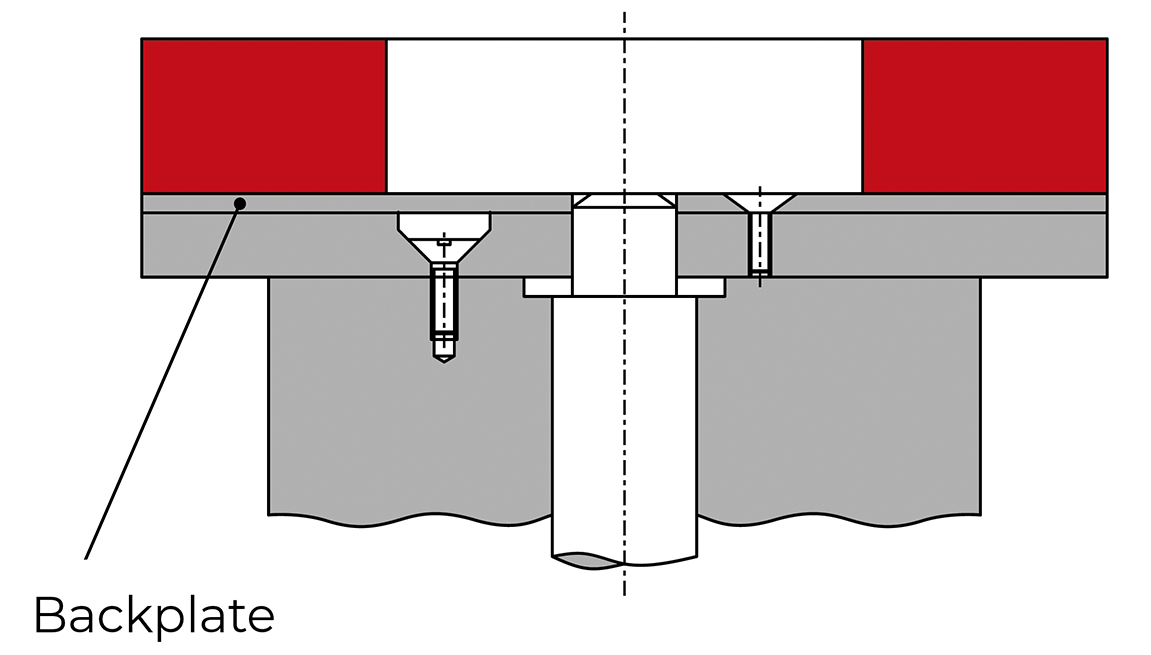

Mounting system in case of grinding wheel cemented to a backplate and bolted to the machine spindle

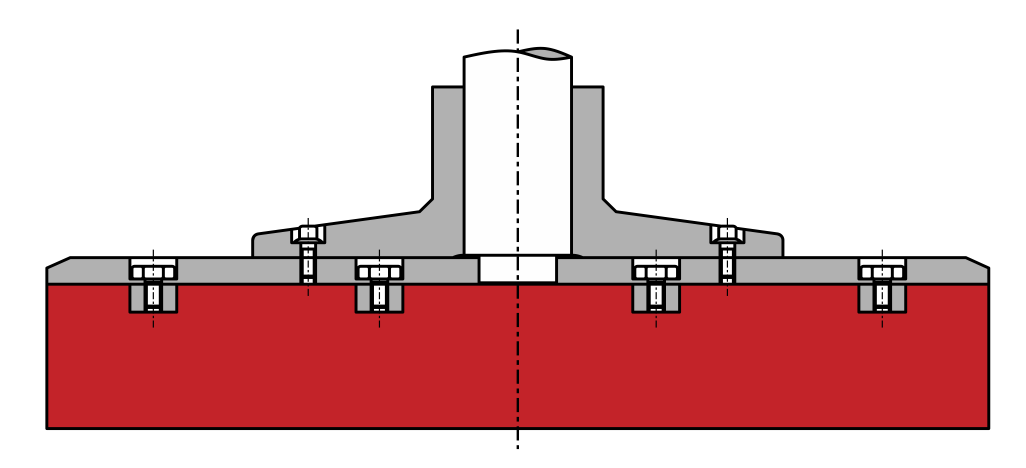

Mounting system in case of grinding wheel bolted to a backplate and bolted to the machine spindle

Correct arrangement of screws and inserts

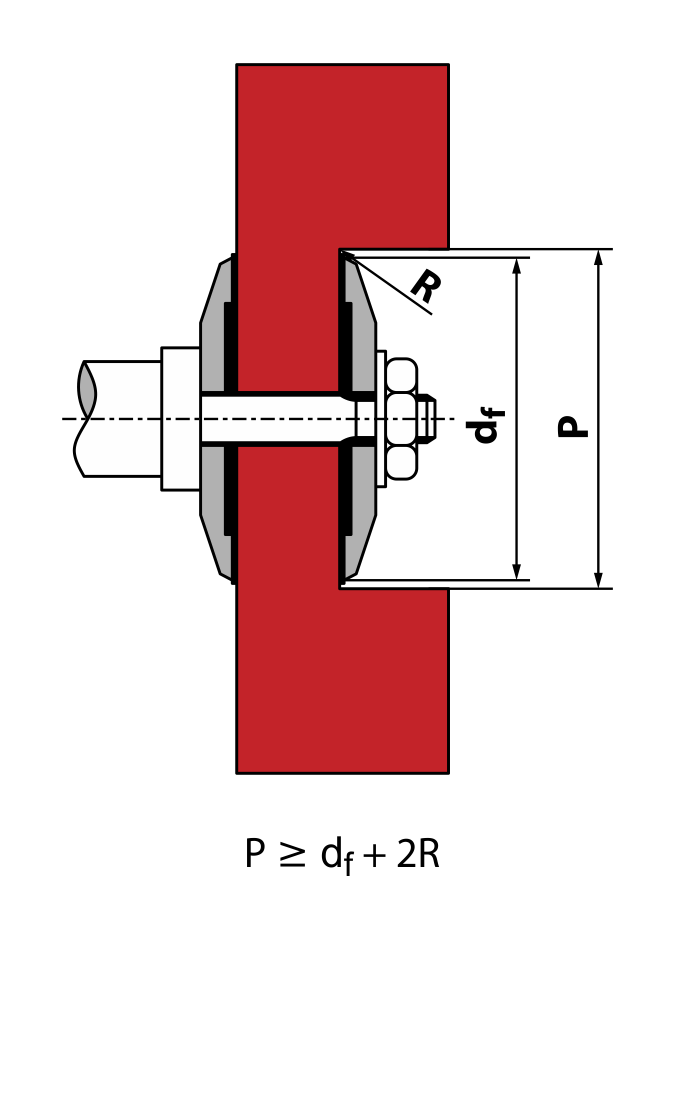

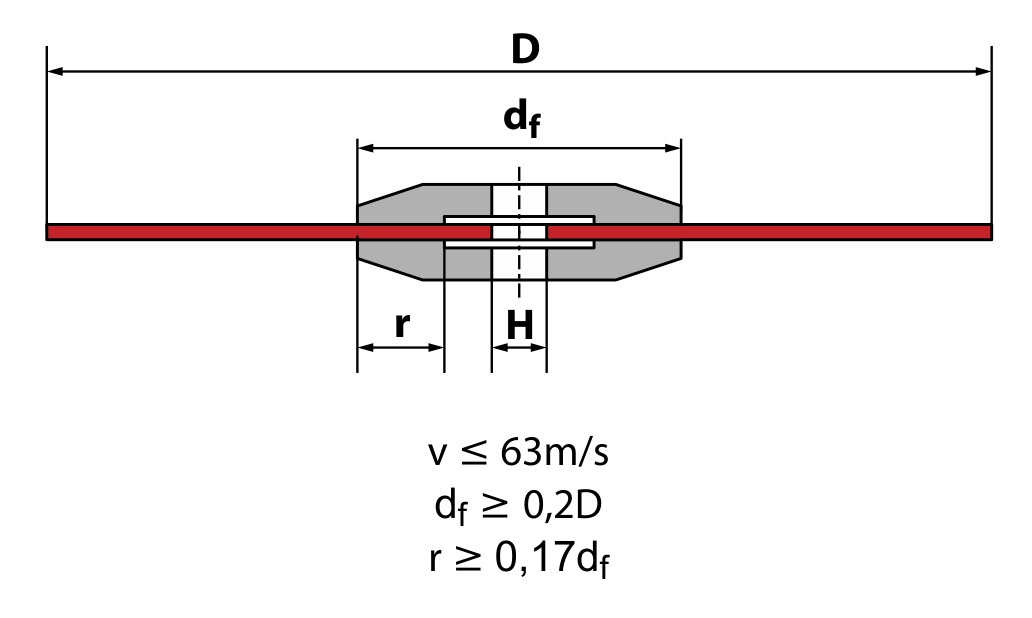

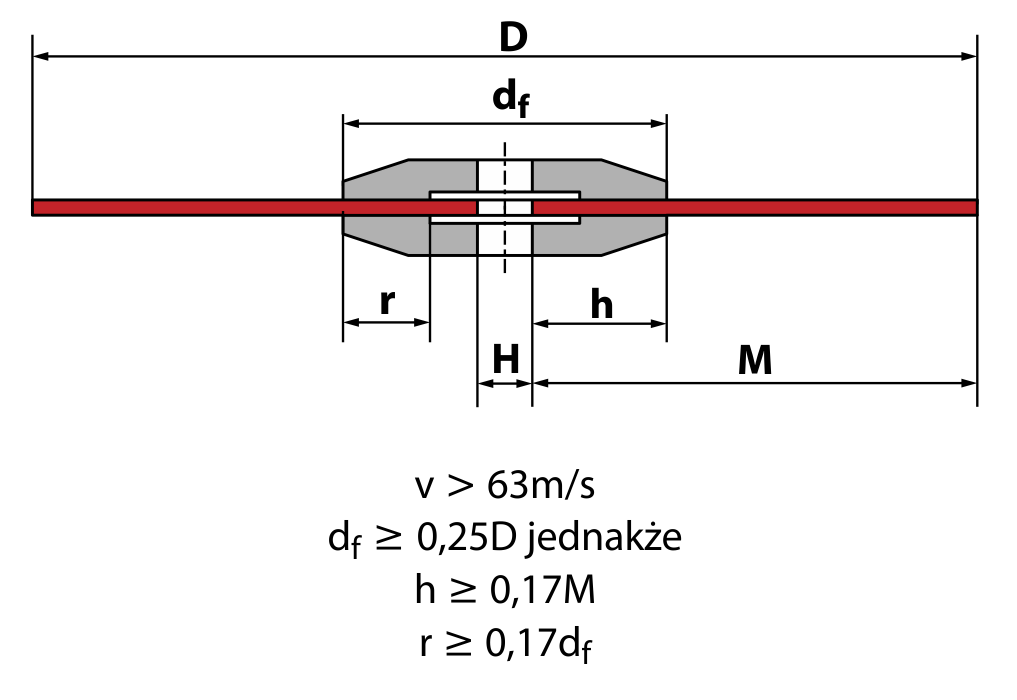

Types of flanges used for mounting flat cutting-off wheels (except wheels with diameter D ≤ 230 mm for hand-held grinders)

In this case straight recessed flanges for flat cutting-off wheels are used. Diameter of the flange depend on the operating speed:

• flange diameter df ≥ 0.2D when V ≤ 63 m/s and hole diameter H ≤ 0.1D

• flange diameter df ≥ 0.25D when V > 63 m/s.

However, if grinding wheel with large bore is used, the area covered by the flange must not be less than 0.17 M.

Straight recessed flange for flat cutting-off wheels when V ≤ 63 m/s

Straight recessed flange for flat cutting-off wheels when V > 63 m/s

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.